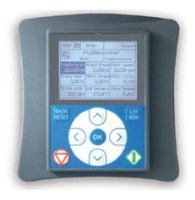

iDrive100 Frequency Regulator

.jpg)

The iDrive100 makes it possible to modulate the speed of the vacuum pump, thus reducing consumption, noise and maintenance costs and enduring maximum stability of vacuum levels during milking.

Advantages:

Lower consumption

Maximum vacuum stability

Minimum noise

New design and multi-function display

Vacuum pumps less subject to wear

Rapid return on investment

Easy to install and to gauge

Fits to vane, lobe or liquid ring pumps

Characteristics:

iDrive100 can govern one or more parallel or cascade pumps

The new “Milk+” software, in synergy with the reliable sensor, guaranteed a swifter response, as well as improved vacuum stability, thus making it easier to regulate the useful reserve in accordance with the real demands of the system. This means less waste and less noise in the milking parlour!

iDrive100 can be operated with or without vacuum regulator

The sensor is able to pick up fluctuations of 0.1kPa, ensuring timely intervention on the frequency variator and thus guaranteeing maximum vacuum stability, even when more than one milking cluster is dropped at the same time.

The pre-set parameters guarantee excellent reactivity; the progressive acceleration of the motor is able to avoid pressure fluctuations typically produced when more than one auxiliary pump is set in motion at the same time. The setting of the parameters can, however, be modified to meet the demands of the system.

iDrive100 can rapidly be programmed “on site” using the convenient mini-keyboard, or by connecting it to a PC, or using an Ethernet cable to ensure functioning is monitored constantly during the set-up and milking phases.

The multi-function display makes it possible to view up to 9 parameters at the same time.

Monitoring of motor temperature.

New “winged” design for improved heat dispersion

“Start&Stop” system for optimising the functioning of the cooling fan

Lower consumption thanks to the extra-low energy consumption components.

General switch can be mounted directly on the inverter

Relays can be installed inside the inverters for controlling the auxiliary pumps